AGRO-PV DOME

If we’re to have Renewable Energy (RE) to be 30% of the energy mix of the country by 2030,

we will have to build a lot of solar farms, which need large flat areas of land with max sunlight.

The challenge is the land need of agriculture – the traditional users of such lands in our country.

At some point soon enough (if not already happening right now), there will be fierce competition for such ideal lands.

We cannot have all the RE we want, but not eat.

The AGRO-PV Dome is an innovative way to have both production of clean power and agriculture from the same plot of land in sustainable manners.

This is OREC (Oregon Renewable Energy Center) and Oregon Tech in action!

Related Videos

AGRO-PV DOME – DESIGN CONCEPT

Achieving the Net Zero Emissions scenario by 2050 requires more solar energy production [1]. Meeting these growth demands will require building many new photovoltaics (PV) plants — but not at a cost to traditional agricultural land uses. An emerging strategy is to co-locate photovoltaic arrays with traditional agricultural land uses, a strategy dubbed “dual-use farming” or agrophotovoltaics. In agrophotovoltaics, both solar energy and agricultural crops are produced in the same space. Crops (or livestock) are cultivated beneath or besides a special configuration of solar photovoltaics (PV) panels arrays. This relationship can actually improve farming productivity and the overall production quality of the crops [2].

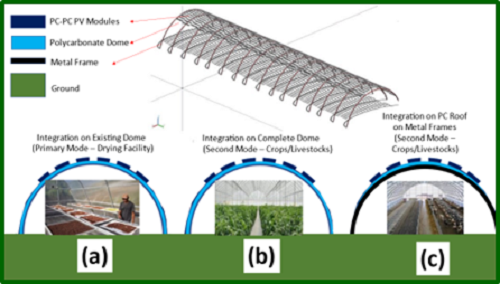

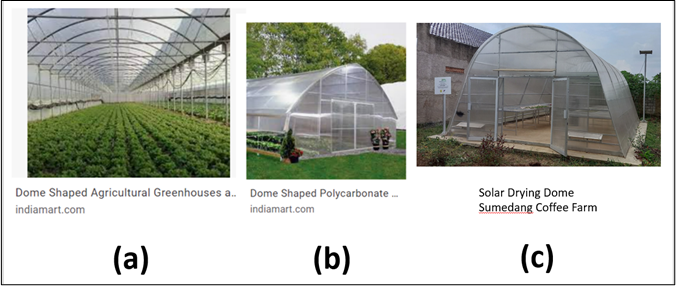

In this project, we design an innovative photovoltaic configuration to optimize solar energy generation in agricultural settings without compromising or competing with agricultural production. We call it the “Agro-PV Dome”. A solar dome (which is a dome-shaped greenhouse structure) is typically found as an integrated part of many agricultural farms all over the world (such as shown in Fig. 1), although more typically farms with crops that need optimum cultivating conditions (temperature, relative humidity, soil conditions, sunlight intensity, etc.), like potatoes or corns. The solar domes are typically made out of strong, stiff and transparent polycarbonate materials, thus allowing sun radiation to help move the humidity away from the crops growing inside the dome as well as the soil, while protecting them from other unwanted environmental conditions (raining, wet or humid air, or even insects, etc.) [2].

In the “Agro-PV Dome”, we aim to integrate this existing dome structure with the most powerful (highest efficiency) form of the solar cell technology in the market today, which is the monocrystalline silicon solar cells [5]. Fig. 2 below is an illustration of the proposed idea. By integrating the monocrystalline solar cells directly onto the polycarbonate sheets that form the dome structures, solar PV energy production may be realized and used for the daily operations of the agricultural farms without occupying any extra land in the farms. The individual solar cells will be placed on the dome structure, such that there would be still spaces in between them, such that it would still allow sufficient sunlight intensity and radiation to come inside the dome and do the function of cultivating or drying the crops, such as illustrated in the Fig. 2 below. The idea would certainly work for existing domes used for drying and storing agricultural products, but it might be further extended to non-drying agricultural crop growth purposes, ie. normal cultivating of crops (especially those with rather tight requirements for temperature, humidity, soil condition and sunlight intensity). The basic idea is that the photovoltaics arrays could be further designed and configured to be on the roof structures of the agricultural land used for crop growth. Crops (or even livestock) may be cultivated beneath or besides this special configuration of solar photovoltaics (PV) panels arrays. This configuration could actually improve farming productivity and the indeed overall production quality of crops, like potatoes or corns (the energy generated from the roof of the dome could be further used to control the ambient inside the dome with smart and precision farming techniques – Internet of Things and Artificial Intelligence (AI) – often allowing even faster drying process and higher quality crops) [3,4]. In addition, of course, the farmers will generate clean energy which they could use to offset the meter from the electricity company, or simply use it directly for daily operation of the farms.

The use of monocrystalline silicon solar cells here are justified based on their highest efficiencies, compared to other technologies existing in the market today, like organic solar cells, or thinfilm [5]. In addition, the silicon solar cells (mono or poly) are also the most mainstream off-the-shelf technology available in the market todays at scales. The challenge is of course integrating them onto the curved surfaces of the polycarbonate materials of the dome. We know that silicon is a naturally brittle material, and silicon solar cells (especially the latest, cutting-edge generation is cut almost razor-thin, at 120-180 microns [6]) are indeed fragile. They break easily – how could we laminate them onto some curved surfaces of the polycarbonate materials? There are two key technical challenges here. First, integrating brittle silicon solar cells onto curved surfaces, and secondly, integrating them onto polycarbonate sheets (front and back, ie. instead of glass front sheet and PET backsheet of typical PV module design, both front and backsheets will have to be made out of polycarbonates).

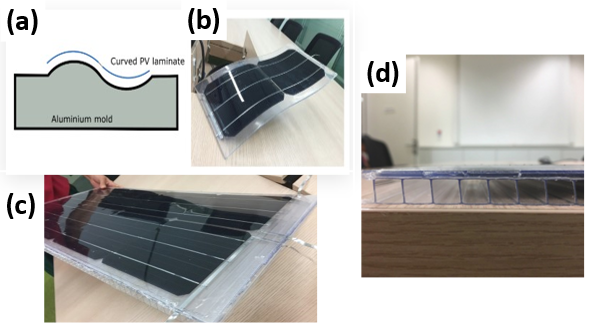

One of the Primary Investigators (PI’s) of this proposal (PI Budiman) has developed the key technology solutions to enable the integration of silicon solar cells with curved polycarbonate sheets during his previous academic career in his laboratory in the Singapore University of Technology and Design (SUTD), Singapore [7,8]. The first issue is how to integrate brittle silicon solar cells onto curved surfaces, and he has demonstrated the enabling solution [7] using all off-the-shelf materials typically used in a conventional PV module design, except of course the front and backsheets. The prototype resulting from the technique developed at his lab in Singapore is shown in Fig. 3(a,b) below. Lab-scale prototypes of silicon solar cells (1x1 and 1x2 cells) integrated onto curved surfaces were demonstrated. The second issue relates to the rather poor adhesion of EVA encapsulant [8] with the polycarbonate surfaces. EVA as we know was developed mostly for good adhesion with glass frontsheet of traditional PV modules. Nevertheless, it is one among very few most used as mainstream encapsulant materials in off-the-shelf PV modules available in the global market todays. Thus, PI Budiman’s group in Singapore was determined to make polycarbonate materials to bond better with EVA. In one of PI Budiman’s recent work [8], the lab-scald prototypes were again demonstrated to show the feasibility and efficacy of the concept.

Design Merits

These key technological solutions will hence enable the real-scale development of the Agro-PV dome concept (as shown in Fig. 2) that we propose in this article. This agrophotovoltaic solution represents a form of the dual-use farming concept which could be a promising solution to the combined increase in demand for solar energy with the agricultural use of the land. We aim to build the AgroPV Dome prototype that would demonstrate the efficacy of the concept and the promise for scaling it into large-scale standard photovoltaics structures that meet the demand for flexibility, modularity, scalability, minimum land occupation, mechanical performance, and that can be deployed in farms without hindering crops growth and farmer activities. The Agro-PV Dome could indeed enhance the outcome quality of the agricultural production, by improving the productivity of the cultivating as well as drying steps, as integrated part of the overall farming productivity of the agricultural setting [3,4]. PI Budiman through his previous project in Indonesia [3,4], have indeed demonstrated the efficacy of similar dome concepts but with smart and precision farming techniques (using IoT and AI) in speeding up the drying process of coffee from 3-4 weeks (using traditional drying) to mere 3-4 days using what they developed, built and called as “Smart Dome 4.0”. The Agro-PV Dome that we propose in this article differs significantly (from Smart Dome) through the direct integration of the silicon solar cells onto the dome surfaces. The “Smart Dome 4.0” was still built with standard solar PV modules and installation [3,4], ie. beside the dome itself – thus it still occupies some agricultural land space. The Agro-PV Dome will need ZERO additional land space in the agricultural setting. This is indeed yet another experience of the PI’s, as well as key building block, in this proposal which would increase the confidence of our success in implementing the Agro-PV Dome concept in real, meaningful scales.

This will be a breakthrough solution which will increase solar energy production, reduce capital and installation costs, align with current supply chains, work in diverse real-world conditions, and make life easier for farmers. This “Agro-PV Dome” represents a form of the dual-use farming concept which could be a promising solution to the combined increase in demand for solar energy with the agricultural use of the land. We aim to build the AgroPV Dome prototype that would demonstrate the efficacy of the concept and the promise for scaling it into large-scale standard photovoltaics structures that meet the demand for flexibility, modularity, scalability, minimum land occupation, mechanical performance, and that can be deployed in farms without hindering crops growth and farmer activities. This concept is an opportunity for developing new PV configurations that use off-the-shelf materials to optimize solar energy generation in agricultural settings without compromising or competing with agricultural production. Obviously, there is a tradeoff between the amount of solar PV energy generated vs. the agricultural productivity of the dome agrivoltaics structures.

Technological Merits as a New Agrophotovoltaics Solution

• flexibility

• modularity

• scalability

• minimum land occupation

• mechanical performance, and

• that can be deployed in farms without hindering crops growth and farmer activities.

Model AGRO-PV Dome – Prototype Design and Development

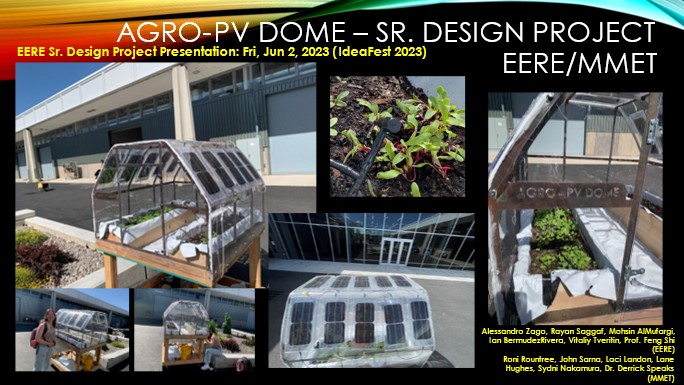

In 2022-2023 academic year, a joint group of EERE (Electrical Engineering and Renewable Energy) and MMET (Manufacturing and Mechanical Engineering Technology) students worked collaboratively to design, develop and build the model (small scale) Agro-PV Dome and they have successfully presented their work in the IdeaFest 2023 in Oregon Institute of Technology OIT, as shown in Fig. 4.

The Model AGRO-PV Dome was successfully built through close collaborations between EERE Students Alessandro Zago, Rayan Saggaf, Mohsin AlMufargi, Vitaliy Tveritiin and Ian BermudezRivera and MMET Students Roni Rountree, John Sarna, Laci Landon, Lane Hughes and Sydni Nakamura, under the supervision of Prof. Feng Shi (EERE), Prof. Arief Budiman (Director of OREC) and Dr. Derrick Speaks (MMET). The students, Alessandro, Rayan, Mohsin, Vitaly, Ian, Roni, and John were doing this as part of their Senior Design Project and they have now graduated proudly from OIT – and three of them have successfully received job offers to work in Solar Photovoltaics (PV) industry in Silicon Valley Bay Area! Laci, Lane, and Sydni are currently assisting in the planning and building of the panels for the real scale AGRO-PV Dome.

Real-Scale AGRO-PV Dome – Design and Development

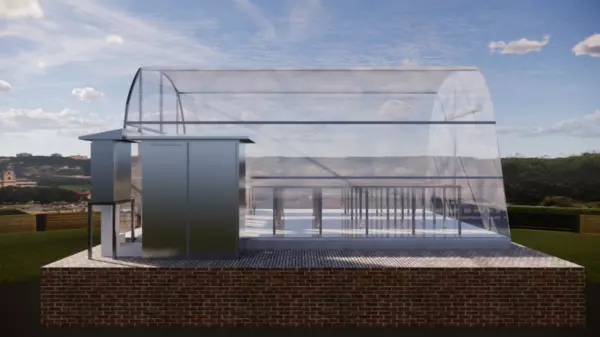

Next, the AGPV team at OREC is now already working to build the real thing – the real-scale Agro-PV Dome!

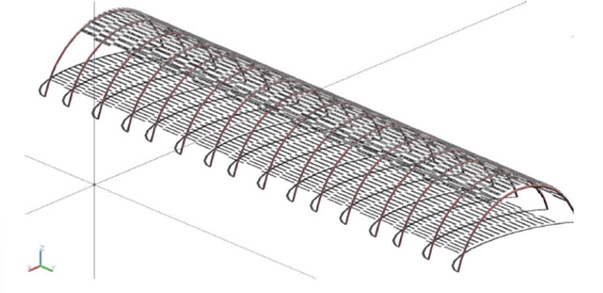

It will be built on a plot of land in OIT Klamath Falls by Summer 2024. Itd dimensions are 8m (width) x 6m (height) and 10m (length). It will be on a plot of land that is 8m x 10m flat area with good amount of sunlight in our campus in KF. The structure will have energy generated from the integrated photovoltaics and will be energetically self-sufficient for the agricultural production operations inside (eg. optimizing temperature and humidity inside the greenhouse). Hence, it will be not only not hindering crops growth and farmer activities inside, but it will even enhance the crop growth and productivity of agriculture!

So, stay tuned in this channel!

Important Vocabulary

Net Zero Emissions Scenario – a situation where global greenhouse gas emissions are in balance with emission reductions. (i.e. carbon dioxide in = carbon dioxide out)

Polycarbonate – A group of thermoplastic polymers that have carbonate in their chemical structure. IT is used commonly in engineering because it is tough, easy to work with, and transparent.

Internet of Things – physical objects with sensing and processing abilities.

Micron – one micron is equal to one millionth of a meter or 1,000th of a millimeter.

EVA Encapsulant – A thermoplastic copolymer that is comprised of ethylene and vinyl acetate and displays adhesive properties.

Efficacy – the ability to produce an intended result