Solar cell technology remains the most cost-effective way to commercially harness solar power for conversion to electricity. However, silicon is a very fragile material, by nature. Crack will inevitably occur – it’s just a matter of time (and wind, and snow, or birds hitting them, or people stepping on them).

The current method of alleviating it is at best just trying to detect it by electroluminescence. It’s too little too late. By the time cracks are detectable by EL method, they are “adult” cracks – they are already too big to halt. Cracks tend to keep propagating (ie. getting larger) as they exceed their critical crack size.

In Crack Catcher AI, we aim to stop cracks in silicon solar cells when they are still babies. Nip it in the bud. Before they achieve their critical crack size. We use fundamental Fracture Mechanics combined with the aids of Artificial Intelligence. Enter CRACK CATCHER AI!

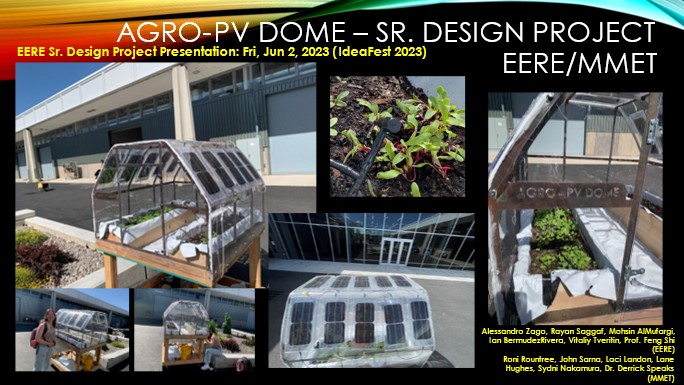

If we’re to have Renewable Energy (RE) to be 30% of the energy mix of the country by 2030,

we will have to build a lot of solar farms, which need large flat areas of land with max sunlight.

The challenge is the land need of agriculture – the traditional users of such lands in our country.

At some point soon enough (if not already happening right now), there will be fierce competition for such ideal lands.

We cannot have all the RE we want, but not eat.

The AGRO-PV Dome is an innovative way to have both production of clean power and agriculture from the same plot of land in sustainable manners.

This is OREC (Oregon Renewable Energy Center) and Oregon Tech in action!

The battery has become a critical component in our daily lives – from our smartphone, laptop to electric vehicle/transportation. We need our batteries to have capacity to hold more power, longer, lighter and cheaper. To achieve higher power capacity, but lighter and cheaper, one crucial component in the battery cell is the anode.

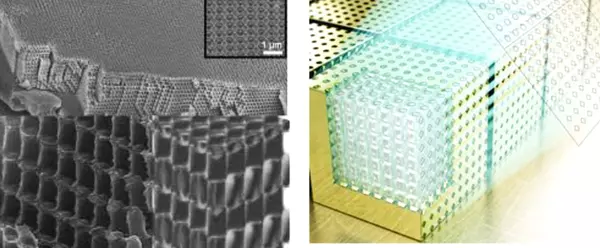

The best design for battery anodes in the Lithium-Ion Battery (LIB) is 3D lattice structure such as shown in the figure below. The 3D lattice structure – especially when it is in nano or micrometer scales – allows the highest surface-to-volume ratio which then leads to max power per unit weight.

The issue is the cost. Most fabrication methodologies involve using very sophisticated equipment and thus expensive. Our team at Oregon Renewable Energy Center (OREC) pioneers a low-cost method – enabled by Additive Manufacturing – in producing these 3D microlattice structures for next-generation LIB so our smartphones could hold more power longer but cheaper. And TESLA’s electric vehicles could be the Volkswagen of our era – the vehicle for the mass.

Wind is the second-largest zero carbon electricity source in Oregon state. Oregon’s climate is windy – thus provides great potential for wind renewable energy for the state – but also icy in some regions especially in winter. Often, locations that have the most potential to generate substantial wind power are also remote and potentially very cold. This leads to an increased risk of turbines operating with ice which, in turn, leads to reduced performance or even a complete freezing of the system.

Ice often increases vibrations in the system, reduces power output, increases maintenance cost by accelerating wear-out and even stopping power generation all together. These are concerns for Wind power generation in remote locations in Oregon. The WIND project (Wind Turbine Blades with Deicing Thinfilm Materials) is aimed to solve this problem with novel thin film materials to help protect and de-ice wind turbine blades.