WILSONVILLE, Ore. – Oregon Institute of Technology (“Oregon Tech”) mechanical engineering students Davia Fleming and Jacob Allemann were not spending their spring break taking a breather. Instead, they were improving safety for healthcare workers by using 3D print technology to create protective shields for frontline medical workers. With some help from faculty members, thus far 40 face shields have been made, with another 90 in production. The students are also making valves through a 3D printing process that will be able to adapt/convert CPAP/BiPAP machines—commonly used to treat sleep apnea—into ventilators.

“We’re an engineering school, so I thought that there’s got to be something that we can do to help,” Davia said, who is a senior at Oregon Tech’s Portland-Metro campus in Wilsonville. “I went online and researched what there were shortages of and found some Open Source software for making face shield visors using 3D printers.”

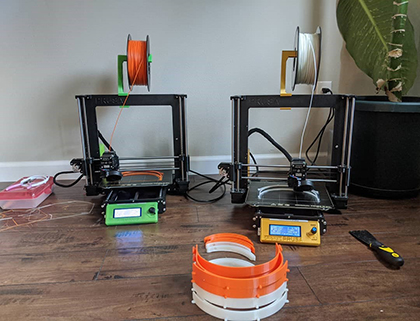

With fellow Oregon Tech student Jacob Allemann, also a senior, Davia had two of the campus’ 3D printers from the prototype lab delivered to her home since she couldn’t work on campus due to the stay-at-home directive. At first using her personal supply of printer materials, Davia and Jacob got busy taking shifts to continuously print the visor component of the face shields. Aided by faculty members Dr. Mike Myers in Mechanical Engineering, Dr. Chitra Venugopal in Renewable Energy Engineering and Dr. Greg Pak in Natural Sciences, the students have produced about 40 visors so far and are working with Dr. Venugopal and staff lab technician and electrical engineering student Richard Ellis to laser cut the acetate shields for attachment to the visors; the first shipment will go out this week. This team is also preparing 3D printed ventilator adapters. The students and faculty estimate that another 70 will be done by next week. Once the first shipment goes out, the production team will focus on digital manufacturing of ventilator adaptors/converters and their distribution to the local healthcare community.

Earlier this week Oregon Tech was awarded a $10,000 grant from the Ford Family Foundation in Roseburg, Oregon. They made emergency funds available “to support rapid response efforts to alleviate the hardships many rural families and organizations are experiencing as a result of the COVID-19 pandemic” so that the project could continue with its production and distribution of the PPE and the conversion of CPAP/BiPAP machines into ventilators.

In all, the student/faculty team are manufacturing respirator masks with changeable filters, printing 3D face shields, and converting CPAP/BiPAP machines into ventilators using resin printed valves and Arduinos. All Oregon Tech faculty had to quickly transition to all-remote teaching and learning in spring term, but still took time out of their hectic schedules to support this student-driven project.

HP in Vancouver, Washington has also been helping with the project, donating their shield components to Oregon Tech through a connection of Dr. Pak’s. Oregon Tech then completes the final assembly, distribution and donation logistics.

Dr. Pak, who teaches at Oregon Tech’s Portland-Metro Campus in areas such as Anatomy & Physiology and Immunology said, “When COVID-19 broke loose across the state, Davia immediately deployed her expertise and inventiveness rather than taking a break after finals. She didn’t let the virus and the need to stay at home stop her, but instead reached out to get 3D printers delivered to her house by faculty. Davia’s and Jacob’s enthusiasm is an energy force that knows no barriers. They are the type of Oregon Tech students whose inventiveness is boundless, especially when there is real human need.”

Dr. Pak has been reaching out to regional hospitals and clinics including Salem Hospital (Salem, OR) to help support their need of the PPE demand to protect their doctors, nurses and other medical staff. The team is also sending some of the shields to Sky Lakes Medical Center in Klamath Falls, Oregon, where the university’s main campus is located, right across the street from the hospital. Oregon Tech also recently lent Sky Lakes several ventilators from its Respiratory Care bachelor’s degree program in order to help it meet growing demand as positive cases increase in Klamath County. Director of Laboratory Services at Sky Lakes Medical Center, Meredith Case, who is an alumna of Oregon Tech, requested face shields from Oregon Tech. Dr. Pak said, “Meredith is one of our Medical Lab Science graduates, and it truly means a lot for us to extend our commitment to an Owl, and to our already close partner, Sky Lakes.”

Oregon Tech will also be providing its finished products to Salem/Portland donation centers, which have been set up by the state and are accepting PPE donations for many healthcare professionals and agencies. These facilities handle the screening process so that the PPE meets medical standards.

Besides the PPE project, Davia is also project lead of Oregon Tech’s RockSat-C project at the Portland-Metro campus. She and her student colleagues spent much of the 2019-2020 academic year working on a sophisticated payload that will be launched by NASA in June at Wallops Flight Facility in Virginia. The Oregon Tech payload research project was one of only seven in the nation accepted to provide a payload on the rocket.

###